However, precision is only sometimes not guaranteed, even with CNC technology. Continuous quality control is essential to detect deviations and even micrometer-level errors. This article explores the technologies and methods used for quality control in CNC machining.

Key Takeaways

- Integration of quality control in CNC machining produces the desired output with accuracy.

- Inspection of CNC machine products at various stages is as important as quality control.

- Dimensional accuracy is a meticulous process of CNC quality control and inspection.

- Quality control identifies deviations from standards using precision measuring instruments.

Quality Control In CNC Machining

Quality control in CNC machining involves using specific instruments and techniques to ensure that the output meets industry standards and regulations, making it crucial for successful manufacturing. The primary goal of strict quality control is to minimize errors by identifying and addressing them early on. Without effective quality control, defective parts can result in significant financial losses.

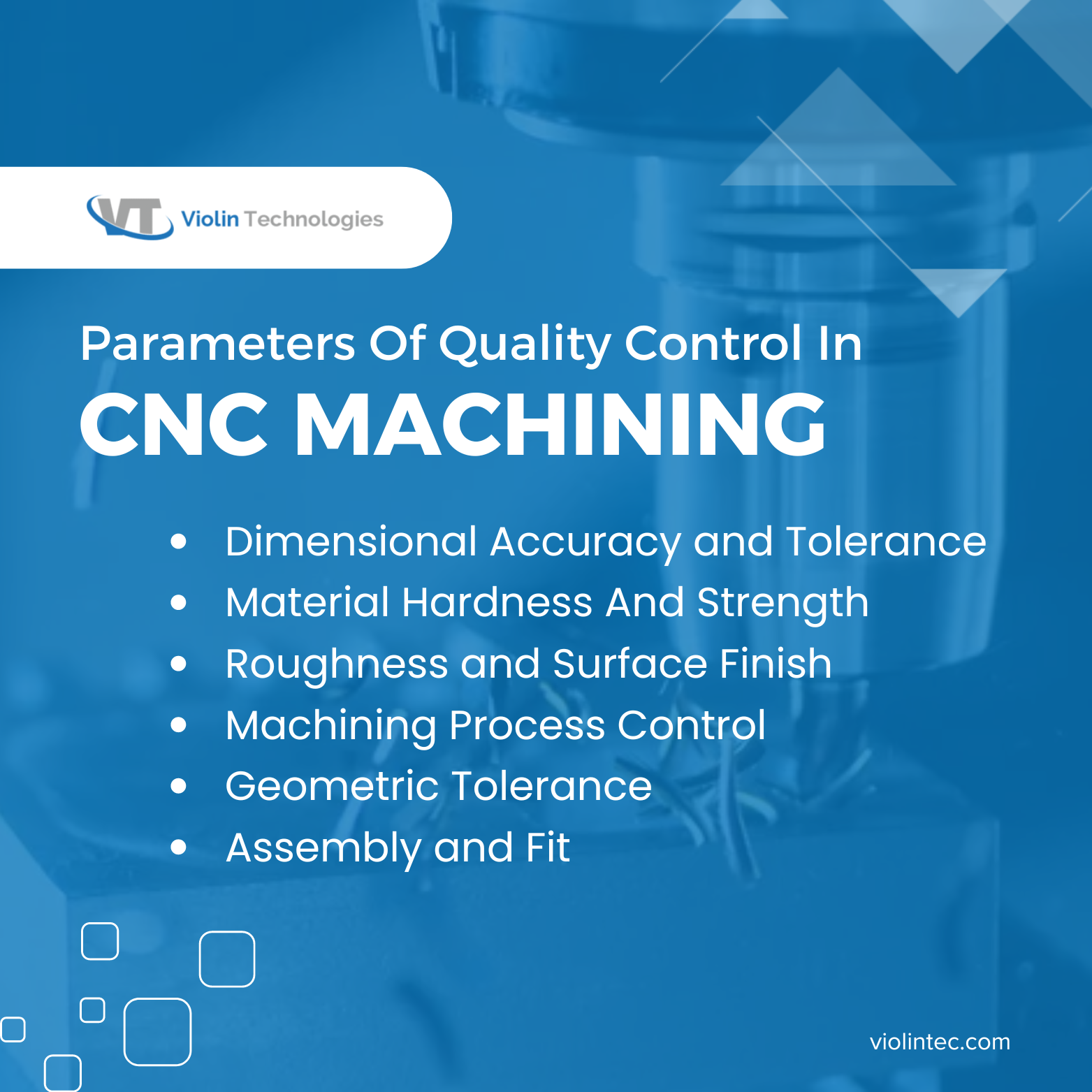

Parameters Of Quality Control In CNC Machining

CNC machines depend on essential factors like precise computer instructions and high-quality raw materials to achieve accuracy and ensure that all components fit together seamlessly, resulting in a product that meets quality standards and customer expectations.

1. Dimensional Accuracy and Tolerance

Dimensional accuracy measures how closely the actual dimensions match the planned specifications. Tolerance allows for a specific range of variation from these planned dimensions. For example, with a tolerance of ±0.002, a part with a 2.000-inch diameter would have acceptable dimensions between 1.998 inches and 2.002 inches.

If no specific tolerance is provided for a part, you can follow international standards, which typically allow for a tolerance of +/-0.1mm.

2. Material Hardness And Strength

The hardness of the material and its strength are vital considerations in CNC machining.

Different applications require materials with specific hardness and strength levels, directly affecting the choice of raw materials and machining techniques. For example, components intended for high-stress environments must use materials that can endure such conditions without compromising integrity.

Thus, thoroughly inspecting material hardness and strength is a critical aspect of the quality control process. This ensures that the final product meets visual standards and also performs reliably under its intended conditions.

3. Roughness and Surface Finish

Surface finish and roughness play crucial roles in the performance and visual appeal of CNC machined parts. The surface finish reveals the precision of the manufacturing process.

High-quality components often demand a smooth, flawless finish devoid of ridges or marks to ensure optimal performance in their intended application. Advancements in traditional machining techniques now provide greater control over surface finish, making it a vital factor in the quality control process.

4. Machining Process Control

Maintaining strict oversight of the entire CNC machining production process is crucial for ensuring quality. This involves:

Monitoring and Adjusting: Continuously track elements like cutting speed, feed rate, and tool wear. Real-time adjustments are essential to maintain output quality. For example, detecting tool wear might require altering cutting parameters or replacing the tool to prevent errors.

Statistical Process Control (SPC): Implementing statistical methods to monitor and manage machining processes is vital. SPC helps identify trends and deviations, allowing for proactive adjustments. This approach ensures consistency and high quality in every CNC machined part.

5. Geometric Tolerance

Geometric tolerancing is a critical aspect of quality control in CNC machining, focusing on applying precise tolerances to geometric features like flatness, straightness, and roundness.

It extends beyond simple measurements, ensuring that each part meets specific geometric requirements essential for its fit, form, and function.

Inspection tools such as CMM (Coordinate Measuring Machines) and the principles of Geometric Dimensioning and Tolerancing (GD&T) play a vital role in achieving this accuracy. They provide the precision needed to evaluate and confirm complex shapes, ensuring that parts meet both dimensional and geometric standards.

6. Assembly and Fit

In the assembly and fit phase, the emphasis is on how well individual components integrate. Precision machining ensures parts align perfectly with design specifications, and dimensional and geometric tolerances are crucial.

A thorough inspection process is essential to confirm that each component fits and operates correctly in the final assembly.

The precision machined components manufacturer in India has the expertise to deliver such results.

Quality Control Standards and Regulations in CNC Machining

Adhering to industry standards is crucial for quality control in machining, ensuring that parts are high-quality, safe, and reliable.

ISO 9001 Certification:

ISO 9001 certification represents a global standard for quality management systems, reflecting an organization’s dedication to product quality, customer satisfaction, and ongoing improvement.

AS9100 for Aerospace:

AS9100, tailored for the aerospace industry, includes all ISO 9001 requirements plus additional quality and safety measures. Compliance with AS9100 is essential for aerospace manufacturers, highlighting the critical role of quality assurance throughout the machining process.

Steps Involved in Quality Control and Inspection

Here are the steps involved in the inspection processes that can be carefully performed with the assistance of the best contract manufacturers in India.

1. Raw Materials Inspection

Raw material inspection is a crucial first step in CNC machining projects. It involves visual inspection of material quality and properties to ensure they meet specifications. This step is vital because the quality of raw materials directly affects the final product’s quality.

2. First Article Inspection (FAI)

FAI is a key quality control step. It ensures that the initial part of production meets design and stringent quality standards. It also helps identify and correct issues early on.

3. In-process Inspection

In-process inspection involves checking dimensions, tolerances, and surface finishes at different stages of machining. Continuous monitoring helps detect and address issues in real time, preventing defects and minimizing rework.

4. Assembly and Fit-Up Inspection

This checks the fit and alignment of machined parts during assembly to ensure proper function and adherence to tolerances.

5. Final Inspection

This thorough evaluation of completed parts ensures they meet all quality inspection standards and specifications before they are approved for use or shipment.

Conclusion

Quality control plays a critical role in CNC machining to guarantee that parts conform to precise standards and specifications. Key parameters such as surface finish and material strength must be carefully assessed. Employing techniques and tools like measurement tools, surface roughness testers, raw material inspection, and hardness testing equipment is essential. Adhering to industry standards is paramount. This comprehensive inspection at various stages necessitates well-trained personnel and rigorous documentation.

Frequently Asked Questions

What are the main steps involved in CNC machining?

The process consists of three essential stages. Firstly, a CAD program is employed to develop CAD 3D models. Next, the computer is integrated into the CNC program and configured. Finally, the machine utilizes materials from the workpiece to create the customized components.

What is CNC inspection?

Quality inspectors play a crucial role in ensuring the final product meets the specific standards for CNC machines. Their inspections of CNC machines and parts during the component’s development are essential for saving time and ensuring consistent quality.

How do you inspect a finished CNC product?

After machining the parts, the final inspection measures dimensions and other critical aspects using a micrometer caliper or a coordinate measurement machine to achieve precision. Identifying errors and taking corrective actions is crucial to ensure consistent, high-quality output.

Aparna Sushumna

About the Author

Aparna Sushumna, a mother to a hyperactive toddler who is all over the house. I aspire to be a decent content developer. A Bachelorette of technology says my qualification but I anticipated being a singer. Thanks to the recession, I dwelled into various jobs, from coding to being a tech support executive to a help desk professional, only to conclude that there is something else I wish to do. Here I am to accomplish my profound passion for content writing. Music, nature, jewelry, beauty, mythology, life quotes, celebs, and their life, being my areas of interest.