Key Takeaways

- ODM companies offer limited customization but not in product features or mechanical design.

- CM allows companies to provide their designs and select a manufacturer.

- Working with CM companies provides supply chain visibility, reducing many associated risks.

- Outsourcing to CM lets companies focus on core marketing and sales capabilities while trusted third parties handle production and shipment.

Understanding ODM And CM

What is ODM?

An Original Design Manufacturing (ODM) is an outsourced manufacturing model where the supplier/manufacturer designs and produces products that are then branded and marketed by a different company.

In this model, the original design manufacturer (ODM) manages the complete product development process. They possess pre-existing designs, tooling, material suppliers, and an established supply chain for the products they produce.

The ODM is also accountable for conducting tests, obtaining certifications, and ensuring quality assurance for the products. Additionally, ODMs retain the intellectual property (IP) rights to the product’s design, patents, and tooling.

Benefits of the ODM Business Model

- Product Development: ODMs handle the entire process from conceptualization to production, including design, engineering, and prototyping.

- Cost Efficiency: Reduces the need for substantial investment in R&D and design.

- Speed to Market: Enables quick market entry with innovative products.

- Reliable supply chains: Access to reliable suppliers and supply chains, thereby avoiding disruptions.

What is Contract Manufacturing (CM)?

Contract manufacturing is a model where a business or client (customer) designs a product and then contracts its production to a manufacturer. The product could be a final consumer product or a component of a larger system.

In this model, the customer (business) designs and develops a unique, functional product and then provides the design to a manufacturer for production. Typically, contract manufacturers do not specialize in specific products or possess pre-made designs, tooling, or products. Instead, they have facilities dedicated to creating custom tooling for various designs.

The manufacturer takes the customer’s design, fabricates the necessary custom tooling, and produces the product and hence retains the IP rights to the product and its tooling.

Benefits of the CM Business Model

- Manufacturing Expertise: Contract Manufacturing can provide specialized manufacturing services without engaging in the product’s design.

- Product Ownership: Clients maintain greater control over product design, quality, and copyright.

- Flexibility: CMs can accommodate various product types and customization based on provided specifications to meet specific market demands.

- Cost Savings: Outsourcing production can be more cost-effective than the in-house manufacturing model.

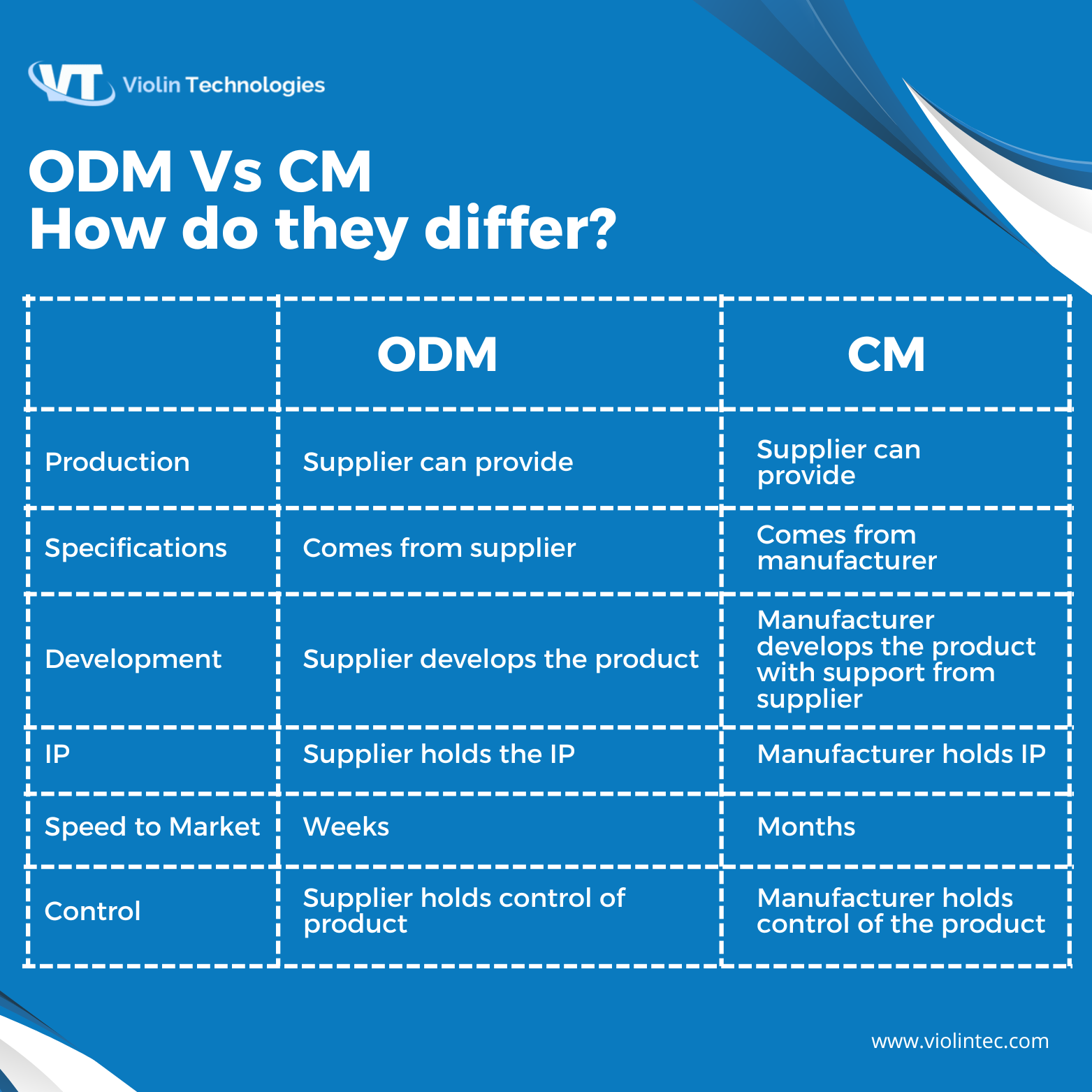

Key Differences Between ODM And CM

While both CM and ODM play vital roles in the same manufacturing services ecosystem, they cater to distinct needs. Here’s a breakdown of the key differences:

Product Design:

- CM: Manufacturers retain complete ownership and control over the product design, including schematics, Bill of Materials (BOM), and functionalities.

- ODM: Ownership typically resides with the suppliers. While they might allow minor tweaks, extensive design alterations are usually limited control.

Innovation:

- CM: Ideal for pioneering a revolutionary product with a never-before-seen design. They ensure your unique creation comes to life exactly as envisioned.

- ODM: Suitable if innovation isn’t your primary focus and you’re comfortable with an existing product design with minor customizations. This route offers a faster path to market with lower costs.

Brand Image:

- CM: Empowers you to establish a unique brand with complete control over product requirements and final presentation.

- ODM: Often involves selling an ODM’s current product with your private label. While some branding opportunities might exist, extensive customization is usually limited.

Cost Structure:

- ODM: Lower upfront investment in R&D but potential royalties or higher unit costs.

- CM: Higher initial costs for product development but lower per-unit manufacturing model costs.

Contract manufacturers enable companies to scale production rapidly while maintaining quality and cost efficiency, allowing businesses to focus on their core competencies.

Understanding The Right Model For Your Business

Considerations for ODM

- Business Objectives: Ideal for companies aiming to quickly introduce new products without heavy investment in design and R&D.

- Cost Efficiency: Reduces upfront costs associated with product development.

- Product Development: Best for businesses without in-house design capabilities or those looking to leverage the expertise of established manufacturers.

Considerations for CM

- Control and Quality: Offers great control over product design, quality, and specifications.

- IP Ownership: Ensures full ownership and protection of intellectual property.

- Flexibility: Ideal for businesses with specific design requirements and customization needs.

- Cost Management: Allows businesses to manage production costs effectively while ensuring a high-quality manufacturing process.

A leading contract manufacturing company in Chennai provides a full range of high-quality production services to various industries, ensuring efficient and reliable manufacturing solutions.

How To Choose Your Champion

There’s no “one-size-fits-all” answer. The optimal choice hinges on your specific manufacturing process, business goals, product characteristics, and risk tolerance.

Here’s a quick reference guide to steer you in the right direction:

- Ideal CM Customers: Holders of innovative product designs, businesses prioritizing brand identity and IP ownership, and companies with high-volume production needs.

- Thriving ODM Clients: Businesses seeking a faster route to market, companies focused on cost-effectiveness, and those comfortable with private-labeled products or minor design modifications.

Don’t be afraid to explore a hybrid approach. For instance, you could leverage an ODM for a product launch and then transition to a Contract Manufacturer for high-volume production once established in the supply chain market. It allows you to benefit from the speed and cost-effectiveness of an ODM initially while ultimately retaining control and lowering per-unit costs for long-term supply chain success. Regardless of your chosen path, fostering a strong and collaborative partnership with outsourcing partners is paramount.

Here are some tips to ensure outsourcing partners have a smooth and successful journey:

- Clearly Defined Communication: Articulate your expectations, product specifications, and quality standards clearly and upfront.

- Regular Communication: Maintain open communication channels to address any concerns or emerging issues promptly.

- Quality Control Measures: Implement strong quality control measures to guarantee your product meets the highest standards.

The best contract manufacturers in India are known for their exceptional quality of product manufacturing and innovative products and solutions in automotive and electronics design services.

Bottomline

Choosing between an ODM and a CM model depends on your business objectives, resources, supply chain, and strategic goals. An ODM model is suitable for companies looking to rapidly introduce new products with minimal upfront investment in design and development.

In contrast, a CM offers great control over product specifications and IP, making it ideal for businesses with specific design requirements and a need for customized manufacturing solutions. Thoroughly evaluate your business requirements and long-term objectives to select the most appropriate model for your manufacturing strategy.

Frequently Asked Questions

What is the difference between ODM and CM?

ODM involves ordering pre-designed products from a manufacturer’s design house, while CM entails producing a uniquely designed product by a third-party manufacturer’s design name.

What is the ODM business model?

The ODM model involves a supply chain of companies that design and manufacture generic products, which are then branded and sold by another firm.

How does IP ownership differ between ODM and CM?

In ODM, the supplier typically owns the IP rights to design, while in CM, the contracting company retains IP ownership of design services.

Which model is more cost-effective?

ODM manufacturing can be more cost-effective than actual product manufacturing due to economies of scale and lower design costs. In contrast, CM might involve higher costs due to customization and production control.

Rasmita Patro

About the Author

Meet Rasmita Patro, a content writer, a former teacher, and a former HR with a passion for storytelling, creating compelling content that engages and informs readers. She has a Master’s in Economics and an MBA degree in Human Resources. Her expertise spans a variety of industries, including finance, healthcare, technology, and others. She has a particular inclination toward crafting blog posts, articles, and social media content that resonates with the target audience. She loves reading different genres of books, love to experiment with cooking, and listening to soothing music.